Sodium chloride (NaCl) is an essential ingredient in the manufacturing of many pharmaceutical products, like the physiological serums and saline solutions. But did you know that its quality directly depends on its storage method? As a manufacturer of white-label products for laboratories and pharmaceutical groups, we know how important it is to preserve its properties to ensure safe and effective products. Here are our tips for optimal storage.

Why is NaCl storage so important?

THE NaCl, although a stable compound, can lose quality if not stored properly. This can have major impacts, including:

- Alteration of purity : Exposure to moisture or contaminants may compromise its composition.

- Non-conformity of finished products : If NaCl is stored improperly, it can affect the quality of the serums or solutions produced.

- Increased risk for patients : In medical environments, contaminated or spoiled NaCl can lead to unwanted consequences.

For laboratories and pharmaceutical groups, properly storing NaCl is a priority to meet regulatory requirements and guarantee user safety.

Our advice for optimal NaCl storage

1. Store in a dry and stable environment

NaCl should be stored at room temperature, ideally between 15 and 25°C. Humidity is its worst enemy. Prolonged exposure to a humid environment can cause it to clump and lose its effectiveness.

2. Use airtight containers

Whether you are storing single-dose saline solutions or large quantities of formulations, it is essential to use sealed, airtight containers to limit any contact with air.

3. Avoid cross-contamination

NaCl should be stored away from volatile or corrosive substances that could affect its purity. Also, ensure that storage areas meet the highest hygiene standards.

Best practices for pharmaceutical laboratories and groups

Traceability and compliance

Every batch of NaCl must be traceable, from sourcing to final storage. Our processes include rigorous monitoring to ensure that each unit meets European and international standards.

Tailored to your specific needs

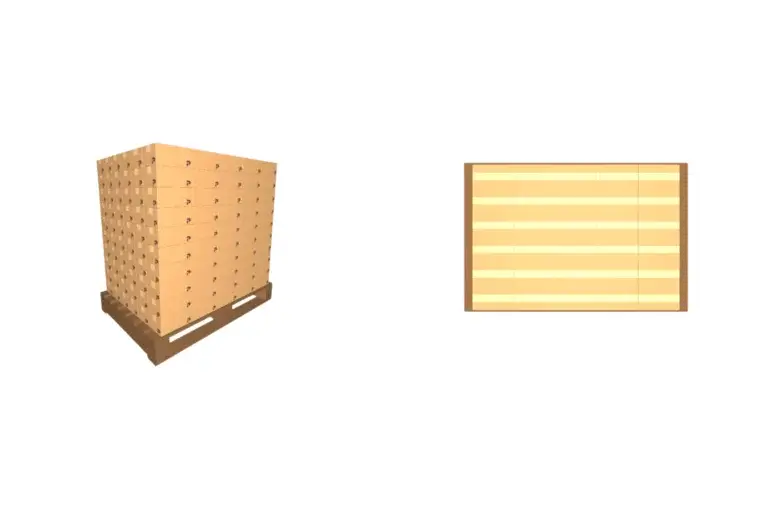

As a white-label manufacturer, we understand that every laboratory has unique needs. We offer packaging tailored to industrial volumes for pharmaceutical groups and laboratories.

Compliance with pharmaceutical standards

Our facilities comply with the good manufacturing practices (GMP) and ISO standards, ensuring storage in the best conditions.

The risks of improper storage of NaCl

Poor storage management can have significant consequences:

- Degradation : Poorly stored NaCl can absorb moisture, forming blocks that are difficult to use.

- Loss of purity : In the pharmaceutical environment, this can lead to non-conformity of finished products.

- Health problems : Saline solutions or physiological serums manufactured with altered NaCl can pose risks to users.

Conclusion

Keep it well NaCl is an essential step in ensuring safe and compliant pharmaceutical products. Whether manufacturing saline solutions, saline solutions, or other products, rigorous storage preserves quality and efficacy. As a white-label manufacturer, we are here to support laboratories and pharmaceutical groups with customized solutions and high quality standards.

Interested in learning more about our practices or white label products? Contact us today.